Waffle Pods

Waffle Pod Slab

What is Waffle Pod Slab?

The Waffle Pod Slab System is a better way of building concrete slabs for new homes, extensions, or commercial industrial buildings.

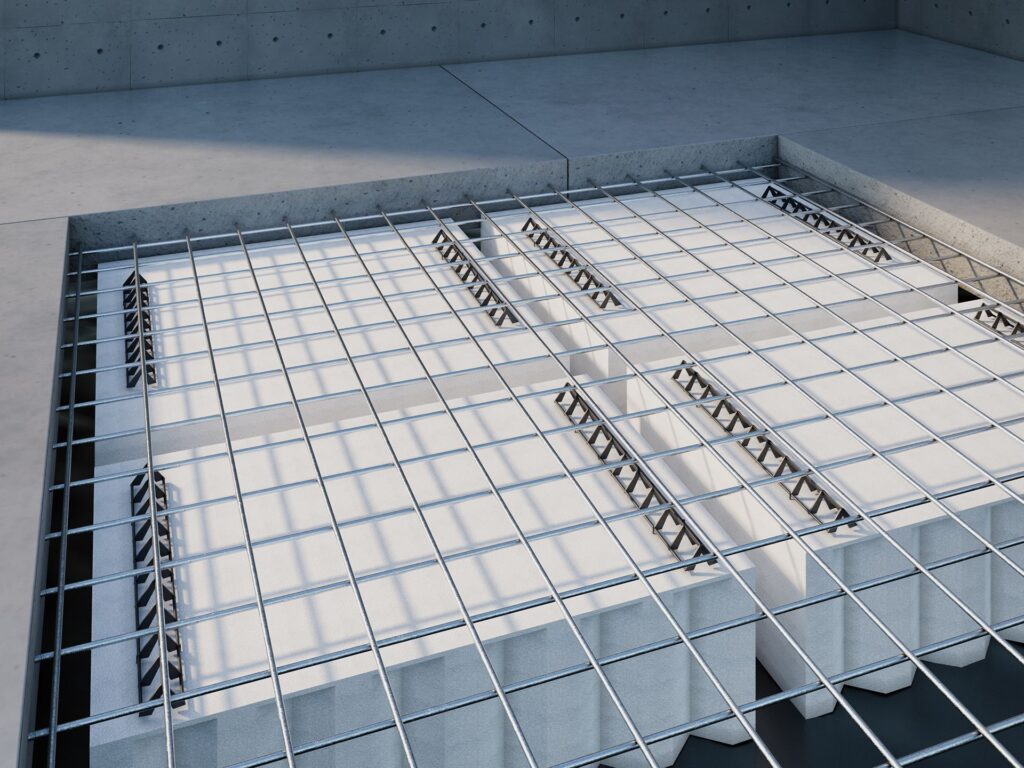

A waffle pod slab foundation is an above-ground foundation used to provide load-bearing capacity in expansive, rocky, or hydro-collapsible soils. The foundation consists of a perimeter flooring and a series of narrow internal beams or strip footings with one-meter centres running each way. Edge formwork makes the sides of the slab, and waffle pods create voids between the strip footings.

The original Waffle Pod foundation system revolutionised the way floors were constructed. Now, over 20 years later, Styropol Waffle Pod floors remain the go-to for builders looking for cost efficiency, quicker construction, and seismic strength.

Waffle Pod floors can be honed to expose aggregates or coloured to become your home’s feature floor.

Advantages of a Waffle Pod Slab

- Reduced Costs Construction can continue in all weather – As the Waffle Pod slab floor is built on the ground, and not in the ground, this means that construction isn’t weather-dependent. The installation can commence and continue even in very wet weather.

- Prompt installation and less waste – As the Waffle Pod slab system is efficiently designed, the labour involved, and therefore time, is heavily reduced. This speeds up installation markedly. Compared to traditional foundations, there is also much less excavated material and waste.

- Seismically sound – In comparison with conventional footings-based foundations, Waffle Pod slabs are seismically strong and perform better in an earthquake.

- Cost-saving – Waffle Pod foundations are cost-saving when compared to traditional foundation methods, as there is no need to dig footings.

- Energy-efficient – Boasting a great thermal rating, insulated Waffle Pod concrete foundations are compatible with underfloor heating.

- Waffle Pod slabs are popularly used for residential and light commercial flooring.

- Less concrete waste

- Minimal disturbance of soil

- Lightweight and easy to handle

- Strong and durable

- Thermal value

- Low water absorption

- Recyclable (sustainable material)

- Manufactured in Australia

- Made from fire-retardant grade raw material

- Ability to accurately predict the required concrete quantities

Waffle Pod Sizes (mm)

1090 x 1090 x 150

1090 x 1090 x 175

1000 x 1090 x 225

1090 x 1090 x 300

1090 x 1090 x 375

Custom thicknesses available upon request

Installation of a Waffle Pod Slab

The Waffle Pod Slab Consists of 4 Main Steps in the Construction Process:

Ensuring the building site is level – If the building site is not level, it is required to cut and fill the site until the surface has become completely flat and a leveled surface has been achieved.

Waffle Pod layout – Once the site has been leveled and first plumbing alongside white ant treatment has been conducted, the pods are ready for layout. The area is then set up with outside edge boards and covered in plastic sheeting. Next, the waffle pods are laid out with spacers in a grid pattern within the formwork.

Reinforcement bars – After this, the reinforcement bars are dropped on top of the spacers between the waffle pods. The top mesh is then laid.

Pouring concrete – Finally, the concrete is carefully poured, ensuring the intersecting areas are completely filled, and the waffle pods and mesh are covered.

Get in Touch with Styropol Industries PTY LTD

We’re here to help with all your polystyrene needs! Whether you have a question about our products, services, or recycling initiatives, our team is ready to assist. Reach out to us today and let’s work together for a more sustainable future.

Visit Our Plant

147 Magnesium Dr, Crestmead, QLD, 4132

Email Us

info@styropol.com.au | sales@styropol.com.au

Call Us

0405964327

Operating Hours

Monday – Friday | 6 AM – 6 PM